Metal structures play a crucial role in the construction and engineering sectors, serving as the foundation for major projects like high-rise buildings, bridges, warehouses, and factories. These structures rely on strict standards to ensure safety and quality, which are essential for protecting lives, safeguarding property, and ensuring the longevity of projects. In this article, we will highlight the key standards that must be met in metal structures to achieve the highest levels of safety and quality.

1. Precise Engineering Design

Engineering design is the first step in constructing metal structures. The design must be based on comprehensive studies of environmental factors, expected loads, and the intended use of the building or structure. Design plans should incorporate safety factors such as resistance to earthquakes, wind, and other potential external forces.

Designs should utilize advanced software like 3D CAD programs, which help simulate the structure’s real-world performance and identify weak points before project execution.

2. Selection of High-Quality Materials

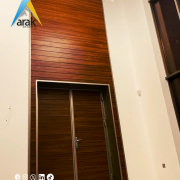

The quality of materials used significantly influences the strength and durability of a metal structure. It is essential to select metals with high resistance to corrosion and impact, such as stainless steel or treated carbon steel.

Key criteria for selecting materials include:

- Mechanical strength.

- Resistance to heat and humidity.

- Recyclability to promote sustainability.

Using substandard materials can weaken the structure and increase the risk of collapse or damage.

3. Advanced Manufacturing Processes

Manufacturing processes must employ the latest technologies to ensure high accuracy and compliance with international standards. These processes include:

- Automated Welding: Offers greater precision and reduces human error.

- Laser Cutting: Provides accurate cuts and minimizes material waste.

- Electroplating: Protects the structure from corrosion and environmental conditions.

Using these technologies reduces overall project costs while improving quality.

4. Continuous Quality Testing

Regular testing of metal components is crucial for ensuring safety. These tests include:

- Tensile and compression tests to verify load-bearing capacity.

- Corrosion resistance tests for harsh environmental conditions.

- Weld inspections using X-ray or ultrasonic techniques.

These tests provide accurate data on whether the components meet required standards.

5. Compliance with Building Codes and Regulations

Metal structures must comply with local and international building standards, such as those set by the American Society of Civil Engineers (ASCE) and ISO standards. Adherence to these regulations ensures public safety and minimizes legal risks associated with construction projects.

6. Resistance to Environmental Factors

Metal structures face various environmental challenges, including:

- Corrosion caused by moisture and salts.

- Strong winds and storms.

- Extreme temperatures.

Structures should be designed to withstand these factors. This can be achieved through thermal insulation techniques and corrosion-resistant coatings.

7. Regular Maintenance

Even with strong designs and high-quality materials, regular maintenance is essential to ensure the safety of metal structures. Maintenance tasks include:

- Inspecting joints and welds.

- Cleaning surfaces and reapplying protective coatings as needed.

- Checking for cracks or damage in components.

Routine maintenance extends the lifespan of the structure and reduces future repair costs.

8. Training of Skilled Workforce

Human resources are a fundamental element in achieving safety and quality. Engineers and workers should be trained in:

- Understanding quality and safety standards.

- Using modern equipment and tools.

- Handling malfunctions or emergencies during construction.

Continuous training improves efficiency and reduces human errors.

9. Sustainability in Metal Structures

With a growing emphasis on sustainable buildings, incorporating sustainability standards in metal structure design and implementation is crucial. This includes:

- Using recyclable materials.

- Reducing energy consumption during manufacturing and installation.

- Designing structures that support renewable energy systems, such as solar panels.

10. Innovation and Technology

Modern technology is a key driver in the development of metal structures. Innovations like 3D printing and artificial intelligence (AI) enhance design and implementation processes. For example, AI can analyze data and predict potential problems before they occur.

Safety and quality are fundamental pillars that must be met in metal structures to ensure the success of any project. Through precise engineering design, high-quality materials, advanced technologies, and adherence to international standards, safe and sustainable metal structures can be achieved. This not only protects lives and property but also enhances a company’s reputation and competitive edge in the market.

Leave a Reply

Want to join the discussion?Feel free to contribute!