Aluminum, iron, and wood are fundamental materials in the fields of industry and design. With the rapid evolution of manufacturing technologies, these materials’ properties have been enhanced, enabling their innovative use in meeting the demands of engineering and architectural projects. This article highlights the role of aluminum, iron, and wood in manufacturing and how advanced techniques are employed to improve their performance and quality.

1. Aluminum: The Lightweight and Sustainable Metal

1.Properties of Aluminum

- Lightweight and easy to shape.

- Resistant to corrosion and rust.

- Excellent conductor of heat and electricity.

2. Applications of Aluminum in Manufacturing

- Construction: Doors, windows, and roofing materials.

- Transportation: Airplanes, cars, and trains.

- Home Products: Appliances and furniture.

3. Advanced Aluminum Manufacturing Techniques

- Casting: Creating complex aluminum shapes.

- Anodizing: Enhancing corrosion resistance and adding aesthetic appeal.

- 3D Printing: Producing precise and intricate components.

2. Iron: Strength and Durability

1. Properties of Iron

- Strong and capable of withstanding heavy loads.

- Fully recyclable and environmentally friendly.

- Affordable and widely available.

2. Applications of Iron in Manufacturing

- Construction: Structural frameworks and bridges.

- Heavy Machinery: Industrial equipment and cranes.

- Metal Furniture: Durable and weather-resistant products.

3. Advanced Iron Manufacturing Techniques

- Casting: Pouring molten iron into molds for customized shapes.

- Laser Cutting: Precise cutting of intricate designs.

- CNC Machining: High-precision shaping of iron components.

3. Wood: The Versatile Natural Material

1. Properties of Wood

- Renewable and environmentally friendly.

- Lightweight and easy to process.

- Excellent insulator of heat and sound.

2. Applications of Wood in Manufacturing

- Furniture: Tables, chairs, and cabinets.

- Interior Design: Walls and ceilings.

- Artistic Creations: Sculptures and decorative items.

3. Advanced Wood Manufacturing Techniques

- Digital Shaping: CNC machines for cutting intricate shapes.

- Thermal Treatment: Improving resistance to environmental factors.

- Laser Engraving: Adding decorative patterns and designs.

4. The Role of Modern Technology in Manufacturing

1. Automation

- Robots enhance production speed and accuracy.

- Reduces human error in manufacturing processes.

2. 3D Printing

- Enables the creation of complex components using materials like aluminum and treated wood.

- Minimizes material waste and improves production efficiency.

3. Laser Technology

- Used for precise cutting and engraving of metals and wood.

- Reduces time spent on complex tasks.

4. Material Treatment

- Powder Coating: Adds a protective layer to iron and aluminum.

- Anodizing: Improves aluminum’s resistance to external factors.

- Thermal Pressing: Strengthens wood and increases durability.

5. Diverse Applications of Aluminum, Iron, and Wood

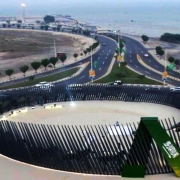

1. Construction and Building

- Aluminum: Used for windows, doors, and corrosion-resistant structures.

- Iron: A key element in structural frameworks.

- Wood: Adds aesthetic value to ceilings and interior walls.

2. Industrial Sector

- Aluminum: In lightweight machinery and electronic components.

- Iron: For heavy machinery and equipment.

- Wood: In packaging and producing transport crates.

3. Artistic and Decorative Use

- Aluminum and Wood: For modern decorative designs.

- Iron: Creating metal sculptures that combine strength and artistry.

6. Challenges in Manufacturing Aluminum, Iron, and Wood

1. High Material Costs

- Solution: Using recycled materials to lower expenses.

2. Environmental Impact

- Solution: Adopting sustainable manufacturing techniques to conserve resources.

3. Material Handling Difficulties

- Solution: Leveraging technologies like CNC to simplify processes.

4. Ensuring Quality

- Solution: Using digital quality control systems.

7. The Future of Aluminum, Iron, and Wood Manufacturing

With continuous technological advancements, manufacturing processes for these materials will become more efficient and sustainable. Innovations in 3D printing are expected to enable the creation of unique components that combine high performance with aesthetics. Automation will play a greater role in reducing costs and enhancing production speed.

Aluminum, iron, and wood are fundamental materials across various sectors, each offering distinct advantages and applications. Modern manufacturing techniques such as 3D printing, automation, and laser technologies have improved the quality of these materials and expanded their usability. Arak shadow is dedicated to delivering innovative solutions that leverage advanced manufacturing techniques to meet client needs while achieving the highest standards of quality and sustainability.

Leave a Reply

Want to join the discussion?Feel free to contribute!