Precision manufacturing plays a crucial role in the construction and architectural sectors, significantly enhancing product quality, efficiency, and sustainability. In a world that demands accuracy and efficiency, modern manufacturing technologies have become essential for achieving the highest quality standards. These advancements ensure that architectural products are not only durable but also aesthetically pleasing and functional. This article explores the significance of precision manufacturing in improving architectural product quality and its role in industry development.

What is Precision Manufacturing?

Precision manufacturing refers to industrial processes that utilize advanced technology to achieve high levels of accuracy and quality. This includes CNC (Computer Numerical Control) machining, 3D printing, industrial robotics, and AI-powered manufacturing systems, all of which help minimize errors and ensure consistency in architectural products.

The Importance of Precision Manufacturing in Architectural Products

- Achieving the Highest Quality Standards

- Precision manufacturing ensures high-quality architectural components, reducing defects and inconsistencies.

- Enhancing Sustainability

- It minimizes material waste through optimal resource utilization, supporting environmental sustainability in construction.

- Increasing Production Efficiency

- Advanced manufacturing technologies enable large-scale production in less time without compromising quality.

- Improving Safety and Durability

- Precision manufacturing results in stronger and more durable building materials, reducing structural flaws and enhancing safety.

Key Precision Manufacturing Technologies in Architecture

- CNC Machining: Ensures high-precision cutting and shaping of materials.

- 3D Printing: Allows for the rapid prototyping and development of advanced architectural models.

- Industrial Robotics: Reduces human errors and improves production speed.

- Artificial Intelligence: Enhances manufacturing processes and predicts errors before they occur.

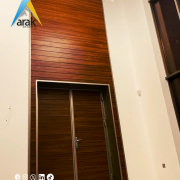

Arak Shadow’s Role in Advancing Precision Manufacturing

Arak Shadow is committed to implementing the latest precision manufacturing techniques to deliver high-quality architectural products tailored to the needs of developers and designers. By integrating sustainable materials and advanced technologies, the company ensures the highest standards of quality and environmental responsibility.

Conclusion

Precision manufacturing is a fundamental factor in improving architectural product quality, promoting sustainability, increasing efficiency, and enhancing durability. By adopting advanced manufacturing technologies, the future of construction and design can be transformed to achieve higher levels of accuracy and innovation.

Leave a Reply

Want to join the discussion?Feel free to contribute!