Wooden doors and windows are timeless elements that combine aesthetic beauty, functionality, and durability. Their production is a detailed process, beginning with a concept and ending with a high-quality finished product. In the modern construction industry, especially for luxury residential and commercial projects, wooden doors and windows have proven to be an essential feature due to their elegance and performance.

This article delves into the journey of manufacturing wooden doors and windows, from the initial idea to the final installation. We will explore the various stages involved, the materials used, the craftsmanship required, and the factors that make wooden doors and windows stand out in any project.

1. Conceptualization and Design

Every successful wooden door and window begins with a solid design concept. This stage is crucial as it sets the foundation for both aesthetic appeal and functional performance. Designers and architects work together to determine the style, functionality, and dimensions required for the doors and windows based on the project’s overall theme.

- Design Style: Whether it’s classic, contemporary, rustic, or industrial, the style of the door or window should reflect the aesthetic of the project.

- Functionality Requirements: This includes factors like insulation, soundproofing, and security. A well-designed wooden window or door should offer adequate performance in terms of these functional needs.

- Customization: Often, these elements are tailored to fit the unique needs of each project, ensuring the perfect balance between form and function.

At this stage, advanced software tools such as CAD (Computer-Aided Design) and BIM (Building Information Modeling) are used to create detailed plans and prototypes, helping ensure that the design will work seamlessly once brought to life.

2. Selection of Materials

The quality of the materials used in the production of wooden doors and windows plays a crucial role in their final performance. Not all wood types are suitable for every application, and choosing the right one ensures durability, stability, and aesthetic appeal.

- Hardwoods: Premium woods like oak, mahogany, and walnut are often chosen for their durability, aesthetic appeal, and ability to withstand the elements.

- Softwoods: Pine, spruce, and fir are more affordable options, often used in residential projects where cost-effective solutions are necessary but still with high quality.

- Engineered Wood Products: These include materials like MDF (Medium Density Fiberboard) and plywood, often used for specific functional benefits, such as enhanced insulation properties or strength in specific applications.

Wood is often treated and treated with finishes to enhance its resistance to moisture, decay, and pests. This is especially important for wooden windows and doors used in outdoor environments or high-humidity areas.

3. Wood Preparation

Once the materials are selected, the raw wood goes through several preparation steps. These steps are essential in ensuring that the wood is ready for shaping and finishing.

- Cutting: The wood is carefully cut into the required dimensions using saws and cutting machinery. Precision cutting ensures that the door or window fits perfectly into the designated space.

- Drying: The moisture content of the wood must be controlled before further processing. Wood that is too moist can warp or shrink over time. Kiln drying or air drying techniques are often employed to reduce moisture to an ideal level.

- Shaping and Smoothing: Once dried, the wood is shaped and smoothed. This step involves sanding and trimming to remove rough edges and create a surface that is ready for finishing.

4. Craftsmanship and Assembly

At this stage, skilled craftsmen take over the manufacturing process, shaping the wooden components into the final design. This stage requires a high level of expertise, as it involves precision work and attention to detail.

- Joinery: The construction of the door or window is carefully executed using specialized joinery techniques such as dovetail, mortise and tenon, or tongue and groove, ensuring that the components fit together securely.

- Paneling: Wooden panels may be added to the doors or windows for added aesthetics or to fulfill specific functional needs, such as enhanced insulation or privacy.

- Hardware: The installation of hardware components such as hinges, locks, and handles is a critical part of this stage. These hardware pieces must be chosen based on their durability, security, and how well they complement the design.

5. Sanding, Finishing, and Staining

Once the wooden doors and windows are assembled, the finishing touches are applied. These are crucial for enhancing both the appearance and durability of the final product.

- Sanding: The door or window is sanded to achieve a smooth and even surface. This helps remove any imperfections from the joinery process.

- Staining or Painting: Depending on the desired look, the wood may be stained to bring out its natural grain or painted to match a specific color palette. This step also involves applying protective coatings to enhance the wood’s resistance to weather, wear, and tear.

- Sealing: A protective sealant is applied to the wood to protect it from moisture, dirt, and other environmental factors. This is especially important for wooden windows and doors exposed to outdoor elements.

6. Quality Control

Before the wooden doors and windows are sent for installation, they undergo strict quality control checks. This step ensures that the product meets both the design specifications and performance requirements.

- Dimensional Accuracy: The doors and windows are checked to ensure that they have been constructed to the correct dimensions and will fit into the designated spaces.

- Performance Testing: Testing may involve ensuring that the door or window meets standards for insulation, soundproofing, and security.

- Aesthetic Checks: The final product is carefully examined to ensure that the finish is even, and the wood has no visible defects, scratches, or discoloration.

7. Installation and Final Touches

After quality control, the wooden doors and windows are ready for installation. This stage involves fitting them into their respective frames and ensuring that they function properly.

- Proper Fitting: The doors and windows are carefully installed to ensure they open and close smoothly, with no gaps that might affect insulation or security.

- Final Adjustments: The hinges, locks, and handles are checked to ensure proper operation, and any adjustments needed for functionality are made.

8. Maintenance and Longevity

Even after installation, the longevity of wooden doors and windows depends on regular maintenance. Periodic inspections, cleaning, and re-finishing can help preserve the wood’s appearance and functionality for years to come. The wood’s exposure to sunlight, moisture, and temperature fluctuations can affect its lifespan, but with the right care, wooden doors and windows can continue to perform beautifully over time.

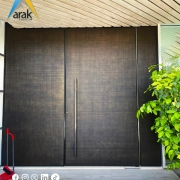

The journey from concept to execution of wooden doors and windows is a detailed and intricate process that combines craftsmanship, quality materials, and expert design. At Arak Shadow, we understand the importance of each step, from selecting the best wood to ensuring the final product meets the highest standards of performance and aesthetics.

By investing in wooden doors and windows, whether for a residential or commercial project, you are ensuring that the final product will be a statement of elegance and functionality. This commitment to quality is what makes Arak Shadow a trusted name in the field of construction and design.

Leave a Reply

Want to join the discussion?Feel free to contribute!